Threaded connections make it possible to join and separate parts easily, even when different materials are involved. They simplify assembly and disassembly and, unlike welding, do not alter the structure of the base material. But how are they made, what exactly is meant by forming, rolling, or cutting—and why are lubricants so important in production?

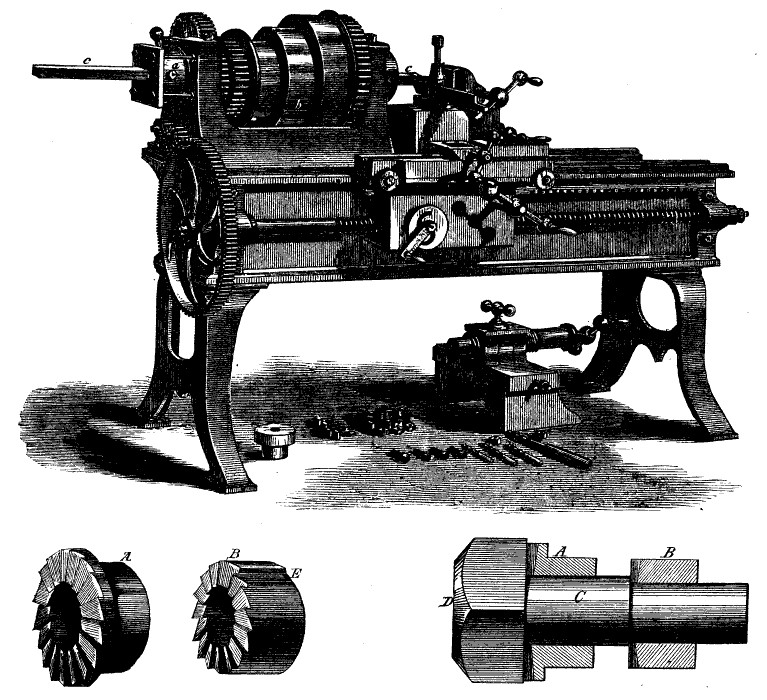

A Look into the History of Thread Manufacturing

The earliest known references to tools for thread production can be found in the notes of the universal scholar Leonardo da Vinci (1452–1519). Whether they were actually used for this purpose can no longer be determined.

The first primitive machine for cutting screw threads was built in 1568 in France. Seventy-three years later, Henry Hindley of York (1701–1771), a renowned clockmaker and mechanic, improved the design and helped establish screw-cutting for practical use. In Germany, screw forges began to appear toward the end of the 17th century, particularly in Westphalia and the Rhineland, though screws were still largely made by hand.

The idea of standardizing came from British engineer Joseph Whitworth (1803–1887). In 1841, he introduced the Whitworth thread, based on the English inch unit, laying the foundation for modern screw connections. Standardization made screws interchangeable and enabled mass production.

Toward the late 19th century, the first attempts were made to form threads by mass production processes, though this was initially limited to hot forming. American William Keane had already considered thread rolling (a form of cold forming) around 1835, but the steel available at the time splintered during cold working. Only after more ductile steels were introduced did the process gain momentum.

Today, several processes for production are established, categorized into cutting and non-cutting methods.

Thread Forming with Cutting Processes

The starting material for cutting processes is usually free-machining steel, which offers particularly good machinability. If preformed blanks are further processed by grinding or turning into precision or necked screws, quenched and tempered steels may also be considered.

Cutting / Tapping

A distinction is made here between internal and external cutting. Internal versions are primarily produced using taps. The first step is to drill a core hole with a standard drill bit. The profile is then cut into this bore with a tap. External versions are cut onto a bolt-shaped blank using a die.

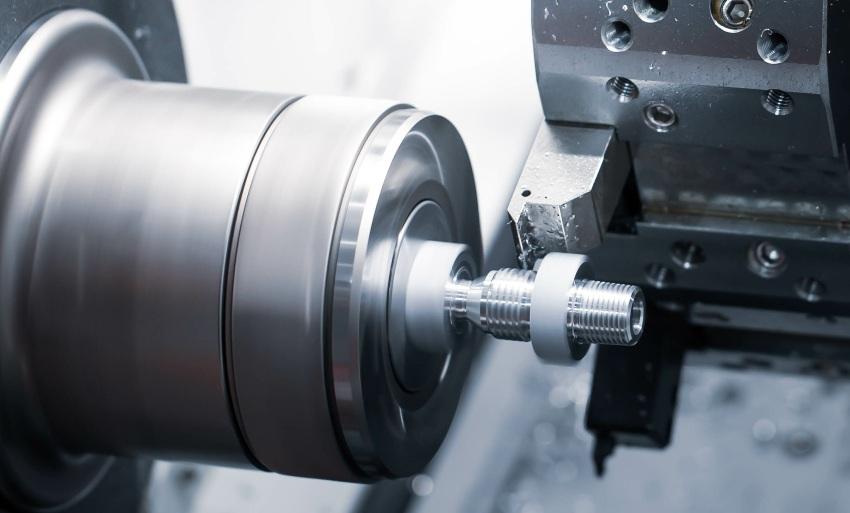

Turning

In this process, a cutting tool is used in a longitudinal turning operation. The profile and positioning of the tool are selected according to the desired shape. In multi-stage production, the cutting tip of the tool is applied repeatedly at the same point on the workpiece. The feed corresponds to the pitch. This method can be used to produce both external and internal forms.

Chasing

Thread chasing makes it possible to manufacture economically on lathes and automatic machines. The tools used for this are available as shank, square, and disk chasers for both internal and external use. They are available as single-tooth and multi-tooth versions.

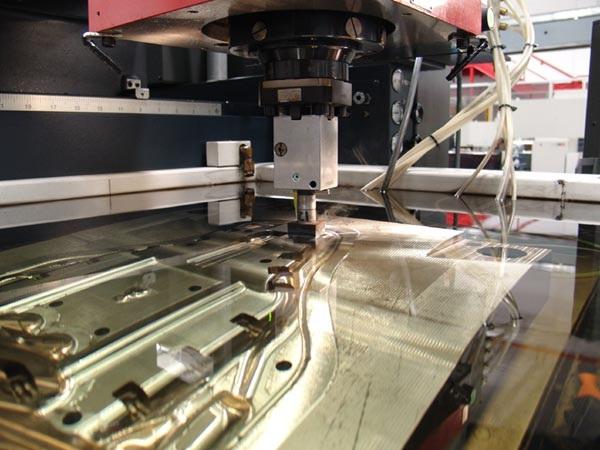

Milling

Thread milling requires machine tools capable of performing movements along the x, y, and z axes simultaneously. This process is mainly used when there are high demands for process reliability and quality. Thread mills are considered problem solvers for special applications. They are rarely used in mass production.

Whirling

Thread whirling is the method of choice where the length is large in relation to the diameter. Also known as thread peeling, this process allows even difficult-to-machine materials to be processed with low tolerances. It is often used to manufacture bone screws from stainless steels or titanium.

Grinding

Thread grinding is primarily used to manufacture threading tools for internal forms. However, it can also be used to produce rolling dies for external ones. One of the biggest advantages of this process is the extremely high-profile accuracy achieved by using ceramic-bonded grinding wheels.

EDM (Electrical Discharge Machining)

EDM is mainly used for producing internal shapes in difficult-to-machine materials. The tool electrode, made of brass, copper, or steel, corresponds to the profile and is driven into a pre-drilled core hole in the workpiece.

Thread Forming with Non-Cutting Processes

In non-cutting production, a distinction is made between hot forming (smaller batch sizes, large fasteners) and cold forming (larger batch sizes). All standardized screws and nuts today are produced by non-cutting methods. For safety components, non-cutting forming is often even required. Non-cutting methods bring several advantages:

- no interruption of the grain flow in the material

- lower stress concentration

- faster production

- no chip formation

- fewer cutting errors

- and a smoother surface structure

Rolling

Thread rolling is often used in screw production. The tools used for this are pressed onto the workpiece with high pressure, resulting in permanent plastic deformation.

For forming to work, the material must be cold-formable. For pointed types, the elongation at break should be at least five percent. The upper tensile strength limit is about 246,000 psi (1700 N/mm²). Typical materials for fasteners with rolled profiles are:

- free-machining and construction steels,

- high-alloy, corrosion- and acid-resistant steels,

- aluminum and copper wrought alloys with a copper content of at least 60 percent.

Sufficient material thickness is required to form in this way. This depends partly on the material itself and partly on the type and depth of the desired profile.

Pressing / Flow Forming

Thread forming by pressing is another process which is used to produce round profiles in sheet metal. A rotating roller is inserted into a pre-drilled core hole while another roller is applied from the outside. The contour is formed in this stepwise process by displacing the material.

What Role Do Cutting and Forming Lubricants Play in Thread Production?

No matter the method—rolling, cutting, chasing, or milling—threads cannot be produced reliably without lubricants. Especially in cutting, the need for lubrication is often underestimated, which frequently results in significantly shortened tool life. Lubricants lower the temperature and reduce friction between the workpiece and the tool, which in turn reduces wear.

Lubricants are indispensable in non-cutting forming, as sliding occurs between the workpiece surface and the tool. Forming lubricants (generally non-water-miscible) ensure that production runs smoothly. They prevent material build-up, which could cause rough surfaces or even tool breakage. In addition, they help dissipate the heat generated during forming. Residual lubricants remaining on the workpiece provide a degree of corrosion protection but often need to be removed before further processing steps.

Kluthe Magazine

Kluthe Magazine