« Your Options for Surface Coating »

The term hardmetal coating can refer to two different processes: applying a hardmetal layer to conventional metals, or enhancing existing hardmetal components with highly wear-resistant materials. These composites consist of a metallic binder, known as the matrix, combined with hard non-metallic phases that provide the exceptional wear resistance.

How Does Materials Science Define “Hardness”?

Around 200 years ago, geologist Friedrich Mohs ranked minerals according to how easily they could be scratched by another material. The stone capable of scratching all others was the diamond, the hardest natural material. Talc, which could not scratch any other, was placed at the bottom of the scale.

Hardness, then, is the material property that describes a substance’s ability to resist penetration by another solid material.

To determine hardness more precisely, a standardized test body is pressed into the surface with a defined force. The smaller the resulting indentation, the higher the material’s hardness. However, high hardness usually goes hand in hand with high brittleness, which can lead to fracture under sudden impact. Hardmetals combine the required hardness with the necessary toughness.

How Hardmetals and Their Coatings Are Made

To create a composite of metal and hard phases, the powdered hard materials are either mixed into molten metal or pressed together with metal powder and then sintered. To coat these materialss, surface technology mainly uses chemical vapor deposition (CVD) or physical vapor deposition (PVD).

Metal surfaces can also be provided with coatings through:

- Plasma-transferred arc welding

- High-velocity oxygen fuel spraying (HVOF)

- Arc spraying

- Laser spraying

Which Hardmetal Components Are Coated?

Hardmetal is inherently very wear-resistant. That is why heavily stressed components—such as metal-cutting tools or valve inserts—are often made from this material. The cutting edges of tools have a significant influence on dimensional accuracy, shape precision, and surface quality, and due to their geometry, are especially prone to wear. To achieve economically reasonable tool lifespans, these areas are coated with cutting materials. The main application is the coating of indexable inserts used for turning and milling tools.

Coating Hardmetals Using Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a surface treatment method based on the reaction of a gas mixture with the material’s surface. The result is the formation of solid compounds that bond with the substrate. These reactions take place in a vacuum at temperatures between 1650°F and 2010°F. The resulting layers—typically made of titanium nitride (TiN), aluminum oxide (Al₂O₃), or titanium carbonitride (TiCN)—are extremely thin, uniform, and well-adhered.

The process is particularly suitable for coating parts with complex geometries. However, the high thermal load can lead to distortion and microstructural changes in the base material. For this reason, PVD is more commonly used for this purpose.

Coating Hardmetals Using Physical Vapor Deposition (PVD)

In physical vapor deposition, the coating materials are vaporized and then condensed onto the part surface under vacuum. Upon cooling, the desired coating—again typically TiN, Al₂O₃, or TiCN—is formed. The process temperature ranges from 750°F to 1110°F. The coating thickness is controlled by the deposition time and may range from a few nanometers up to several microns. However, coating thickness is limited—if the layer becomes too thick, it may peel off.

Hardmetal Coatings on Metallic Substrates

Metals can be coated using thermal methods. In this case, powdered mixtures of metals and hard materials—or semi-finished products—are heated and applied to the metal surface. This allows cost-effective base materials such as steel or aluminum to be upgraded with high-performance, wear- and corrosion-resistant layers.

Coating Metals Using Plasma-Transferred Arc Welding (PTA)

Plasma-transferred arc welding uses an electric arc to generate the heat required for surface coating. The arc forms in an inert gas (such as argon or neon) between two electrodes. The heat transforms the gas into plasma, which is a mixture of electrons, gas ions, and neutral gas atoms. This energy is sufficient to partially melt the metal surface and fully melt the hardmetal powder. The result is a surface layer that is metallurgically bonded to the base material.

Advantages of this process include a high degree of automation and high deposition rates—up to 44 lbs/h.

Coating Metals Using High-Velocity Oxygen Fuel (HVOF) Spraying

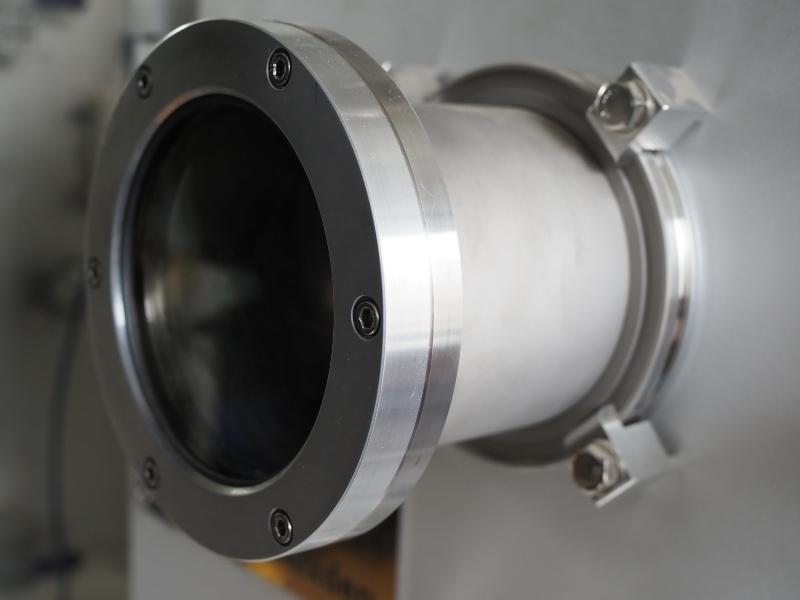

In HVOF spraying, fuel is combusted with oxygen under high pressure in a combustion chamber. This generates extremely high temperatures—over 5400°F—that melt the hardmetal powder or rods. The molten particles are then accelerated to speeds of up to 1800 ft/s through a nozzle and impact the base material.

This creates highly adhesive and extremely dense coatings with thicknesses of just a few tenths of a millimeter—typically 0.008 to 0.02 inches. Since the base material only heats up to around 390°F during this process, its internal structure remains unaffected.

Coating Metals Using Arc Spraying

Arc spraying is a surface coating technique in which the coating material is used in wire form and acts as the electrode. An electric arc burns between the two wires, generating temperatures of about 7200°F, causing the wire tips to melt. The molten material is atomized by a gas jet and sprayed onto the metal surface.

For hard coating applications, cored wires filled with hard materials are used. The resulting layers—ranging from 0.008 to 0.8 inches thick—are significantly more porous than those produced by HVOF. However, arc spraying allows for very high deposition rates.

Coating Metals Using Laser Spraying

In laser spraying, a laser beam locally heats the base material until it begins to melt. A nozzle introduces the hardmetal powder directly into the melt zone, where it bonds with the base material. This process makes it possible to apply coatings with precisely defined contours—such as on cutting edges of tools.

Kluthe Magazine

Kluthe Magazine