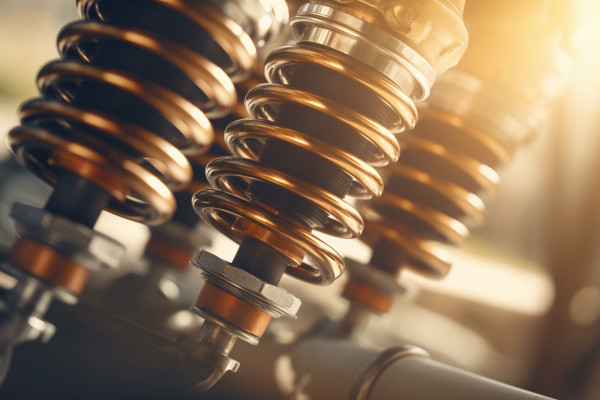

Kluthe Turkey optimizes process in shock absorber production ?

We were able to significantly optimize the manufacturing process of a well-known car and truck supplier for shock absorbers with the help of our cooling lubricant HAKUFORM A 801 TK. The #coolinglubricant is used for grinding processes before and after chrome plating. In the high-pressure process, it operates completely free of foam, something that no other coolant had previously achieved in the demanding periphery of the central plants.

The excellent rinsing behavior further increases process reliability. Thanks to the modern, oil-free formulation, all deposits and clogging of the piping system are proven to be a thing of the past. The #corrosion protection is perfectly designed for subsequent intermediate storage.

#klutheworldwide #KlutheFamily #proud #innovation #quality #hakuform #AdvancedMetalworking #grinding #Machining #metalworking #shockabsorber #coolinglubricants #grindingprocess #processsafety