The Earth Overshoot Day marks the day of the year on which humankind has consumed more natural resources than earth can regenerate in one year. This makes it even more important to make industrial processes more sustainable and to use resources efficiently.

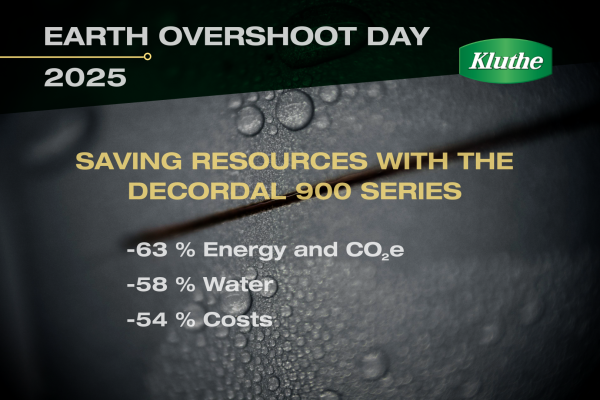

At Kluthe, we focus on sustainable process solutions that increase the efficiency of our customers while also making massive cost savings. One example is our Decorrdal 900 series with thin-film technology - a resource-saving alternative to traditional zinc or iron phosphating.

A customer from the automotive industry has switched its 5-zone spraying system from iron phosphating to our thin-film passivation in the pretreatment of automotive components - with impressive results:

- 63 % energy and CO₂ savings due to reduced application temperatures

- 58% less water consumption with optimized processes

- 54 % cost savings by using resources more efficiently

#EarthOvershootDay #Sustainability #sustainablechemistry #yeswecare