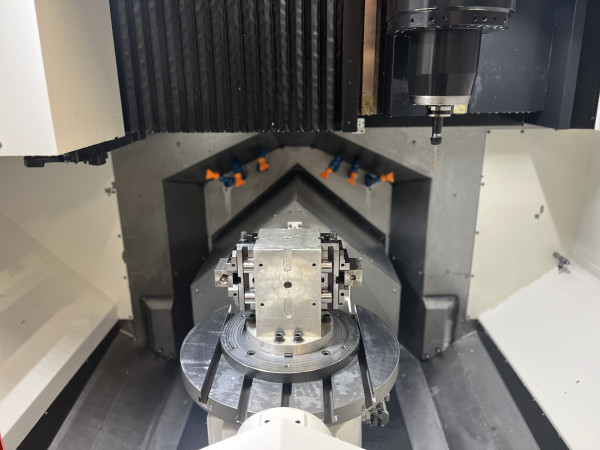

Customer Bedford Engineering reports: how HAKUFLUID 185 contributes to increased efficiency.

At Bedford Engineering, HAKUFLUID 185 is used in CNC machines for turning and milling. Advantagesobserved by the customer:

- Reduced consumption

- No oily residues

- No odour

- Improved foam control

- Solved corrosion issues

- Cleaner machine surfaces & glass

- Similar or improved tool life

- Improved skin conditions on certain operators

#KlutheUK #successstory #Hakufluid #Machining #coolinglubricant #5axismachining #milling #Sustainability