Rusting is the most well-known form of chemical corrosion in metals, but it is far from the only one. Effective corrosion protection can be achieved using specialized chemical substances—so-called corrosion inhibitors—that prevent or at least slow down corrosive material degradation. They work by actively inhibiting or disrupting the chemical reactions that would otherwise lead to corrosion. A corrosion inhibitor either occupies the position that the attacking medium would take or intercepts it. Even very small amounts of inhibitors are sufficient to suppress the corrosion mechanism.

Applications for Corrosion Inhibitors

Corrosion of metals typically involves electrochemical processes. Metals have a lattice structure composed of regularly arranged ions. In the presence of moisture, individual ions can dissolve from the lattice. They then react with oxygen to form rust or other corrosion products. Some of these reactions also involve hydrogen. The resulting compounds are oxides and hydroxides of the base metal. The formation of these corrosion products can be prevented or reduced by eliminating free oxygen or by shielding the surface from moisture. Using corrosion inhibitors is advisable in processes where water-based solutions interact with metal surfaces. Such processes include:

- Heat dissipation via water-mixed coolants in metal cutting operations

- Machine and parts cleaning

- Surface treatment using pickling

- Heating and cooling in water circulation systems and

- Pressure or leak testing of tanks, equipment, and piping

Corrosion protection with inhibitors is also used when moisture from the air can condense on metal surfaces due to temperature fluctuations. Examples include:

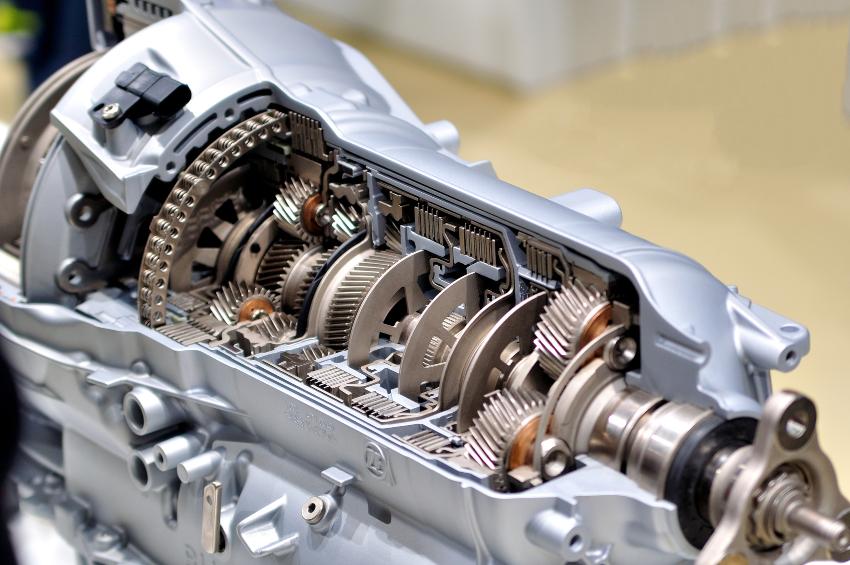

- Operation of engines and gear units

- Transportation of goods

- Use of electrical equipment outdoors

Corrosion Inhibitors in Process Fluids, Coolants, and Cleaning Agents

Coolants, cleaning agents, and process fluids used in surface treatment often contain water-soluble corrosion inhibitors. These chemicals are composed of organic polar molecules, such as hydrocarbons modified with functional groups. Commonly used substances for corrosion protection include compounds based on alcohol, organic acids (fatty acids), or esters. Alcohols contain an -OH group in their molecular structure; acids contain a -COOH group.

Esters are compounds formed from acids and alcohol through the elimination of water. One end of these chain-like molecules aligns with the metal surface, while the other faces the water-based solution. This forms a thin film that prevents direct contact between the liquid and the metal surface. If this film adheres to the surface due to intermolecular forces, the inhibitor is considered physically active. A chemically active inhibitor binds directly to the metal surface and makes it resistant to reactions with other substances. This form of attachment is referred to as adsorption.

Selection Criteria for Water-Soluble Corrosion Inhibitors

The selected corrosion inhibitor must not interfere with the functional properties of the fluid required for the specific process. As a result, a wide variety of corrosion inhibitors are available, and each one is tailored to specific operating conditions.

The cleaning action of many agents depends on the pH value of the solution. For example, acidic cleaners are used for lime-based residues, alkaline cleaners for greasy contamination, and neutral cleaners for general applications. The added inhibitor must be compatible with the required pH level. Cleaning and pickling processes are typically preparation steps for further surface treatment and must not be negatively affected by the corrosion inhibitor. Water-miscible coolants often contain various additives such as emulsifiers, stabilizers, extreme-pressure additives, and biocides.

The selected inhibitor must not chemically react with these substances. For this reason, leading manufacturers such as Kluthe offer process fluids that already contain compatible corrosion inhibitors. Additionally, Kluthe has developed corrosion inhibitors under the product name CUSTOS, which are suitable for use in neutral cleaners and coolants—or even as stand-alone neutral cleaners. These products can also be used in immersion baths for leak testing. In such applications, parts are completely submerged in water. If liquid enters internal cavities, air bubbles reveal the presence of leaks.

Corrosion Inhibitors for Process Water

In many applications, process water is used as an energy carrier. In heating and cooling systems or closed-loop circuits, the high heat capacity of water is used to transport thermal energy. In pressure testing of tanks or devices, the low compressibility of water is utilized. If the material fails under pressure, a gas-based test medium would expand explosively. Water, by contrast, changes volume only slightly under pressure. To prevent corrosion, an inhibitor is added to the process water to bind the dissolved oxygen. This prevents the oxygen from reacting with the metal.

In the past, hydrazine was frequently used for corrosion protection. This nitrogen-hydrogen compound reacts quickly with oxygen even at low concentrations. However, hydrazine is highly toxic and suspected of being carcinogenic. Its use is now strictly regulated and is largely limited to steam generation in power plants, where most other water-soluble inhibitors would not withstand the high temperatures. For all other applications, safer alternatives are available today.

Corrosion Protection in Packaging and Electrical Engineering

To protect against moisture condensation caused by temperature fluctuations, VCI agents are often used. VCI stands for Volatile Corrosion Inhibitor. These substances evaporate and form a protective film on metal surfaces. The vapors can penetrate moisture films and displace water because they are more strongly attracted to metals (via adsorption) than water. VCI inhibitors are applied to packaging materials made of cardboard, paper, plastic film, or foam for use during shipping.

Over time, the inhibitors slowly vaporize and protect the packed components or devices from corrosion. A major advantage of this method is that the vapors can also reach internal cavities—and no cleaning of the items is required afterwards. Volatile corrosion inhibitors can also be used to protect electrical and electronic components. Corroded electrical contacts increase electrical resistance, which leads to energy loss and heat buildup—potentially resulting in fire. In circuits where contact lubricants cannot be used, VCI products provide an effective alternative.

Kluthe Magazine

Kluthe Magazine