« What is this coating process all about? »

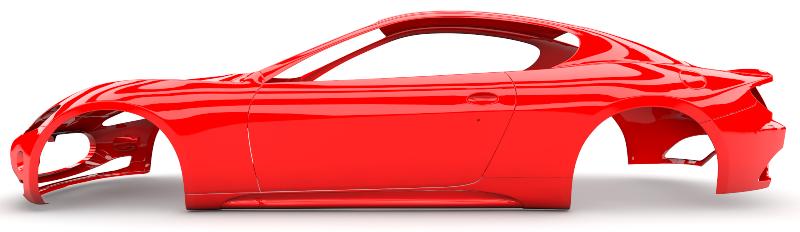

Electrophoretic coating (commonly known as e-coating) is a highly efficient surface pretreatment process that provides superior corrosion protection while ensuring complete coverage of metal components. This process has become essential in industries where durability and uniform protection are critical, especially in automotive manufacturing where it serves as the foundation for vehicle paint systems. In this process, an electric field ensures an even application of paint, even on parts with complex geometries. Depending on the polarity setup, the process is divided into cathodic and anodic e-coating. The paint layers produced through this method adhere strongly to the surface and provide excellent corrosion protection.

Requirements for Electrophoretic Coating

Also referred to as electrophoretic deposition, e-coating is driven by electrical attraction and requires:

- a direct current (DC) power source

- conductive surfaces on the part to be coated

- a counter-electrode

- electrically charged paint particles

- deionized water allowing for free movement of particles

The DC power source creates an electric field between two electrodes. The part to be coated acts as one electrode, while the counter-electrode completes the circuit. This allows current to flow through the liquid bath and return to the power source. Both electrodes are immersed in a bath filled with water containing finely dispersed paint materials, binders, and pigments. This forms a colloidal suspension, where paint particles remain evenly dispersed at the nanoscale. To migrate along the field lines and deposit on the target surface, the particles must have an electrical charge opposite that of the part being coated. Deionized water is crucial; any foreign ions could reach the surface and interfere with the film formation. During the coating process, ions with a charge opposite to the paint particles inevitably form. These move toward the counter-electrode and are removed through a separate filtration loop.

Cathodic or Anodic Coating?

In practical applications, two variations of e-coating are used: anodic and cathodic. If the part is connected as the anode (positive pole), it is an anodic process. A downside to this process, is that the part can partially dissolve, similar to how a sacrificial anode works in corrosion protection. To avoid this, the cathodic process is now more common—where the part is the negative pole—offering improved corrosion resistance.

Step-by-Step Process of Electrophoretic Coating

Pretreatment and Rinsing

Surface preparation is key. Parts are cleaned and often coated with a conversion layer that provides additional corrosion protection and enhances paint adhesion. Common methods include pickling or phosphating. All chemicals used during pretreatment must be thoroughly rinsed off with deionized water to prevent contamination of the e-coat bath.

Paint Deposition

As the part moves through the bath, the charged paint particles travel along the field lines and deposit on the surface. Near the surface, ions interact with the paint particles, neutralizing their charge. In cathodic e-coating, these are hydroxide ions formed by the electrolysis of water. In anodic systems, hydronium ions take on this role. The result is a neutral, water-insoluble paint layer whose formation releases significant heat.

Layer Thickness and Coverage Capabilities

The neutral paint film becomes increasingly insulating, redirecting the electric field toward uncoated areas. As a result, the coating thickness is self-limiting—usually just a few microns (approximately 0.1-0.2 mils)— allowing even the inside surfaces of cavities can be coated. This ability to coat internal surfaces is called “throw power.” Once the entire part is coated, the electric field breaks down, and deposition stops.

Rinsing

After coating, the part is lifted from the bath and sent to a rinsing station, where any residual soluble chemicals are removed from the surface.

Curing

Final coating strength is achieved in a curing oven at temperatures between 355°F and 375°F (180–190°C). During curing, paint molecules chemically bond into long chains, creating a durable, three-dimensional polymer network.

Technical Setup for Electrophoretic Coating

The power supply starts with alternating current (AC), which is converted to direct current (DC) using a device called a rectifier, essentially an electrical converter. Typical voltage ranges from 200 to 300 volts. The rectifier’s terminals are connected to the part being coated and the counter-electrode which stays in the bath. The part is moved through the bath, typically using an overhead crane. Tank sizes are scaled to accommodate parts and can reach volumes up to 105,000 gallons (400 m³) for coating entire vehicle bodies. Pumps continuously circulate the bath fluid, keeping particles suspended and preventing sedimentation. The circulation system includes dosing units for paint replenishment, waste removal modules, and cooling units to maintain optimal conditions. Sensors monitor critical parameters and adjust values in real time to stay within acceptable ranges. With proper control of peripheral systems, bath life can span several years.

Advantages of Electrophoretic Coating

Though the process requires sophisticated equipment, e-coating offers several significant benefits:

- Uniform coating of complex parts, including edges and internal cavities, ensuring long-term protection against corrosion, wear, and road debris.

- The paint layer serves as a highly durable primer that can be painted over, using various systems or it can be left as is, creating the final finish.

- Multi-metal paints allow different metals to be coated simultaneously without switching baths which is ideal for machinery composed of multiple alloys.

- E-coating dramatically reduces material waste compared to other coating processes as there is no overspray, and therefore, no losses.

- Modern e-coats are environmentally friendly and optimized for low energy consumption.

These water-based formulations comply with EPA regulations under the Clean Air Act that limit volatile organic compound (VOC) emissions and OSHA safety standards for coating operations, making them particularly suitable for US manufacturing facilities.

Applications for Electrophoretic Coating

E-coating is commonly used for parts exposed to harsh environmental conditions or mechanical stress. This includes vehicle bodies, truck cabins, cargo beds, construction equipment, and agricultural machinery. It is also increasingly used for tool machine housings and components in crane systems requiring robust corrosion protection.

Kluthe Magazine

Kluthe Magazine