« The Importance of Surface Treatment for Equipment Efficiency »

In common terminology, the phrase “maintenance and servicing of machinery and equipment” is frequently used. Strictly speaking, servicing is a broader category that includes maintenance. The latter ensures continuous trouble-free operation. Learn how optimal machine maintenance helps your equipment withstand normal wear and tear over time and keeps disruptions during production to an absolute minimum.

Purpose of Machine Maintenance

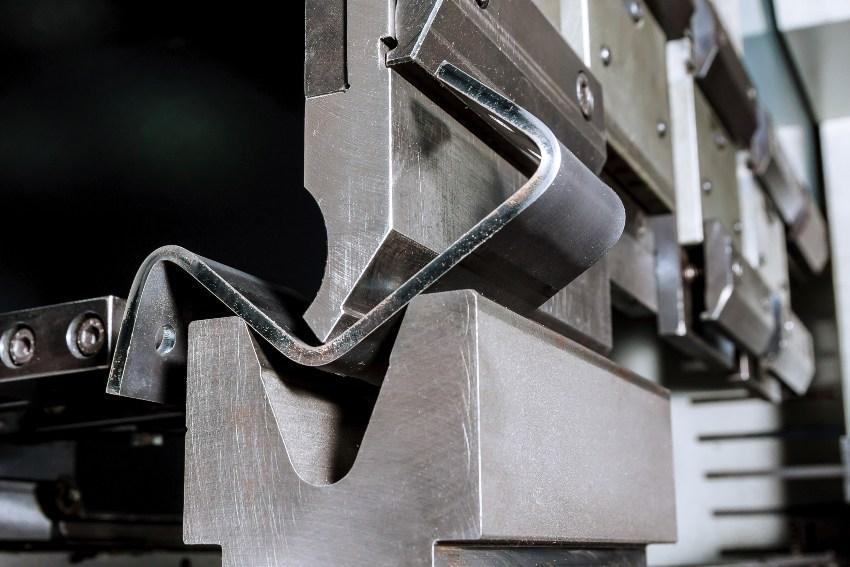

Machines often operate with tremendous force. In mechanical engineering, these forces purposefully shape materials. In the chemical industry, they sustain processes for material transformation. However, these forces also impact the machinery where value is created. Various adverse environmental factors often accompany these stresses. Without countermeasures, these can eventually lead to disruptions in the production process, which may pose significant economic and safety risks.

Machine maintenance aims to minimize these risks, thereby increasing the availability of technology and preventing disturbances. This includes all activities that maintain the functionality and safety of the machinery. On the other hand, repairs restore operational readiness after a malfunction by fixing or replacing damaged components. Along with inspections, which assess the current state of the technology, and improvements that eliminate weaknesses, repairs and maintenance are part of the broader category of equipment maintenance and process control.

Activities in Machine Maintenance

The necessary activities for proper machine and equipment maintenance are outlined in the technical documentation provided by the manufacturers. Manufacturers are obligated to provide operators with comprehensive information on this topic. Additionally, warranty claims can only be enforced if the manufacturers’ guidelines are properly followed. Key maintenance activities typically include:

- Internal and external cleaning of the machine

- Replacing worn parts at the end of their expected lifespan.

- Adjusting machine parts

- Supplying lubricants and supplies

- Checking the function of safety devices

- Documenting the actions taken

- Maintenance of cooling lubricants

Machine Maintenance is Plannable

A significant advantage of maintenance activities is their predictability. Some tasks can be performed during ongoing operations, but many measures can only be completed when the equipment is stopped. To manage work processes economically, it is advisable to establish a machine maintenance schedule. This is particularly practical when maintaining complex systems involving multiple machines working together. If a system stops due to malfunctions in this type of scenario, the loss in production is much greater than with a single machine. For this reason, the chemical industry has always conducted scheduled preventative maintenance, which involves shutting down the entire system. The period of this planned shutdown can be minimized with good preparation. Maintaining individual machines was once seen as unavoidable and is sometimes slightly neglected. However, the advent of robotics in mechanical engineering and the spread of Industry 4.0 have changed this perspective.

Requirements for Machine Maintenance Plans

Machine maintenance plans provide the foundation for thorough preparation and swift execution of maintenance. They compile all necessary information for timely and condition-based maintenance. For cleaning processes, for example, this means specifying suitable cleaning agents, the exact dosage, and the required temperature range recommended in the maintenance plan. Deviating from these specifications can not only compromise the cleaning success but also lead to serious incidents. Therefore, responsible suppliers of cleaning agents like Kluthe, support users with comprehensive advice.

Scheduled Machine Maintenance

Scheduled maintenance activities are carried out periodically according to manufacturers’ specifications or operators’ experiences. The maintenance plan primarily records the following information:

- Deadlines for regular measures (e.g., system cleaning, machine cleaning, replacement of spare parts)

- Detailed description of the activities (e.g., disassemble, clean, assemble, adjust)

- Required qualifications of the employees (e.g., certified electrician)

- Necessary supplies (e.g., cleaning agents, lubricants)

- Needed spare parts (e.g., seals, hydraulic hoses, compressed air lines, filter media)

- Deadlines for the procurement of supplies and spare parts

- Values to be documented after maintenance (e.g., set bearing play, achieved torque)

Condition-Based Machine Maintenance

To fully utilize the lifespan of components, machine care is often performed based on their condition. Assessing this condition is the task of inspections, which are closely linked to servicing. If such condition-based measures are planned, the upkeep schedule must include appropriate threshold values that facilitate decision-making.

Software for Machine Service Plans

As the scale of production facilities grows, so do the demands for equipment care planning. Numerous IT companies offer digital servicing plans to assist with this. These plans are designed to be customizable to the specific local conditions of each company, ultimately leading to significant time and cost savings because tasks like ordering spare parts, adhering to prescribed deadlines, and organizing repair work are simplified.

These plans are further enhanced by augmented reality. tablets or glasses guide employees through the work process. The necessary information is available exactly when the corresponding step is performed. This helps to avoid mistakes and reduce the time spent on equipment and machine maintenance.

Kluthe Magazine

Kluthe Magazine