Paints and solvents often have a distinctive odor, similar to that of common adhesives. This slightly sweet smell is due to the solvent ethyl acetate. In lesser amounts, such as those used at home, there is not much of a health risk. However, when using larger quantities of paints or adhesives at home, work should only be done in well-ventilated spaces. In industrial settings, safety measures must be followed when handling paints and solvents to minimize health risks from these substances.

Which Health Risks Are Associated with Paints and Solvents?

GHS – A Global System for Hazard Identification

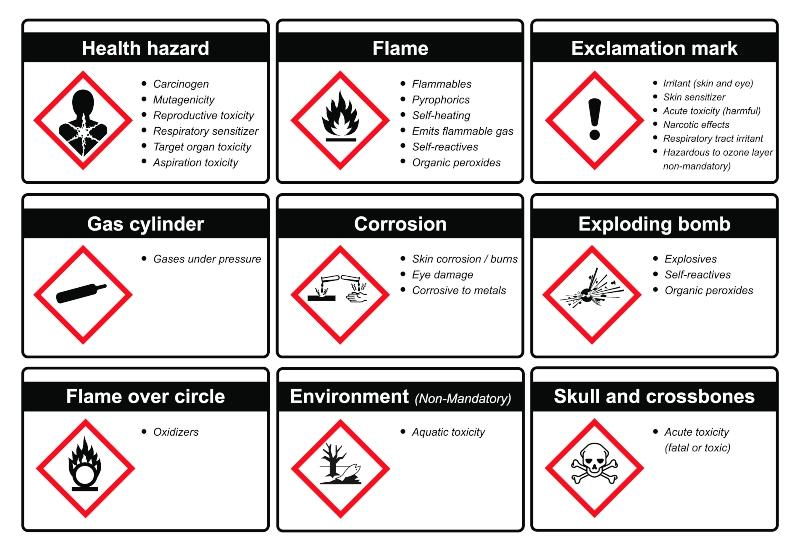

A look at the packaging can help. Every chemical, including surface coatings and their removal products, must be labeled according to the GHS system.

GHS stands for Globally Harmonized System of Classification, Labeling, and Packaging of Chemicals and is a worldwide, standardized system to categorize chemicals based on their risks.

There are a total of nine health hazard classes, which are further categorized based on the degree of danger. Not every substance is equally flammable – some ignite at room temperature and pose a greater risk than others, whose flash point is around 70°C, which is well above room temperature. The H-statements (H stands for hazard) describe specific risks associated with the substance, while P-statements (P stands for precautionary) indicate the safety measures that should be taken. For instance, a corrosive chemical may carry the instruction to rinse eyes with water for several minutes in case of contact.

Health Risks from Paints and Solvents

Health Risks from Paints and Solvents

Different paints contain different binders or solvents. Whether you are working with nitrocellulose paints, water-based paints, UV paints, or PUR (polyurethane) paints, the health risks vary slightly. Nitrocellulose paints, which have a high solvent content, pose a risk in case skin contact or inhalation of solvent fumes occurs.

Working with water-based paints presents health risks associated with the inhalation of paint aerosols and potential skin contact. When working with UV paints, there is an additional risk of skin and eye damage from scattered UV radiation. Inhaling ozone, which can be produced when using UV light, also poses a health risk. When UV paints are used for surface coating, the work is typically done in closed systems with proper exhaust systems. General health risks associated with almost all types of paints and solvents include respiratory and skin hazards.

Safety Measures for Working with Paints and Solvents

For working with paints and solvents, safety measures are implemented at various levels.

Substitution and Technical Protective Measures

If a less hazardous alternative to a paint or solvent exists, such as , one that poses a lower fire or health risk, it should be used. Safety regulations always require replacing a dangerous substance with a less hazardous one if possible. At the same time, technical protective measures are implemented in surface coating and paint processing, such as working in well-ventilated areas and using exhaust systems.

These measures reduce exposure to harmful solvents and aerosols, while also lowering the risk of fire and explosions. Additional fire prevention measures include eliminating ignition sources. This includes not just banning smoking but also ensuring that defective electrical devices, which can cause fires through cable short circuits or electrical sparks, need to be prevented. A spark could be enough to cause an explosion in a vapor/air mixture, as just ten liters of such a mixture can create an explosive atmosphere. Therefore, fire extinguishers should always be within reach.

Even when transferring solvents, static sparks can occur, so equipment should always be grounded. The same safety precautions apply to storing paints and solvents.

Flammable solvents should be stored in plastic containers with a maximum capacity of five liters. The storage area should also be well-ventilated to prevent the formation of explosive atmospheres or the release of harmful vapors. These substances are usually stored in specially ventilated safety cabinets or storage rooms.

Organizational and Personal Protective Measures

Anyone working with chemicals, solvents, and paints should be trained in the proper handling of these substances. Employers are required to provide regular training for employees on how to work safely with hazardous substances. Even the best technical protective measure is useless if not used correctly. Personal protective measures include wearing protective clothing. In most cases, wearing safety goggles is also required, especially when working with UV paints to protect the eyes from harmful UV scatter light. Chemical-resistant gloves prevent the skin from coming into contact with solvents – even small splashes can harm the skin.

The type of glove material suitable for handling specific surface coatings must be determined on a case-by-case basis. In addition to wearing gloves, proper skin care is important. Solvents have a degreasing effect and can dry out the skin over time. Other potential skin risks include redness, scaling, or the development of eczema.

Operational Guidelines and Skin Protection Plan

Every employee who might encounter paints and solvents in their job, should be informed about the hazards, health risks, and protective measures through the company’s operational guidelines. These workplace directives outline the potential risks and necessary safety measures, always using the GHS symbols.

In addition to operational guidelines, there is typically a skin protection plan for handling substances that pose a risk to the skin. This plan outlines preventive measures each employee should follow, such as wearing gloves and maintaining proper skin and hand care. Health risks associated with working with paints and solvents arise from inhaling fumes and aerosols, in addition to skin exposure. Appropriate protective measures can effectively reduce or eliminate these risks.

Safety measures include technical controls, such as working in enclosed systems and exhausting solvent fumes.

Organizational measures include regular employee training and creating work instructions, while personal measures include wearing appropriate protective clothing. By following all these measures, potential health risks from working with paint and solvents can be effectively controlled.

Kluthe Magazine

Kluthe Magazine