To develop effective methods for reducing friction-related losses of material and energy, it is necessary to develop a clear understanding of the mechanisms underlying friction and wear. In this context, the term “tribosystem” was introduced. The prefix ‘tribo-‘ derives from the Greek word tribein, meaning “to rub”. Tribosystems, therefore, include all materials that influence friction and wear. Learn how they help researchers maintain a clear framework by studying these processes and by examining the roles surface technology and chemistry play in this field.

Structure of Tribosystems

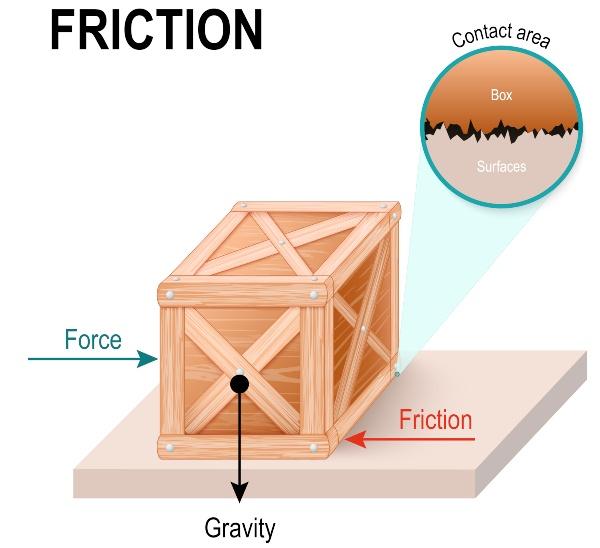

The amount of energy consumed by friction and the amount of material removed by wear depend on the interactions between the substances involved and the conditions under which the movement occurs. If a single component changes, all others will respond in some way. Therefore, the components form a system. A tribosystem consists of:

- Base body

- Counter body

- Intermediate medium

- Ambient medium

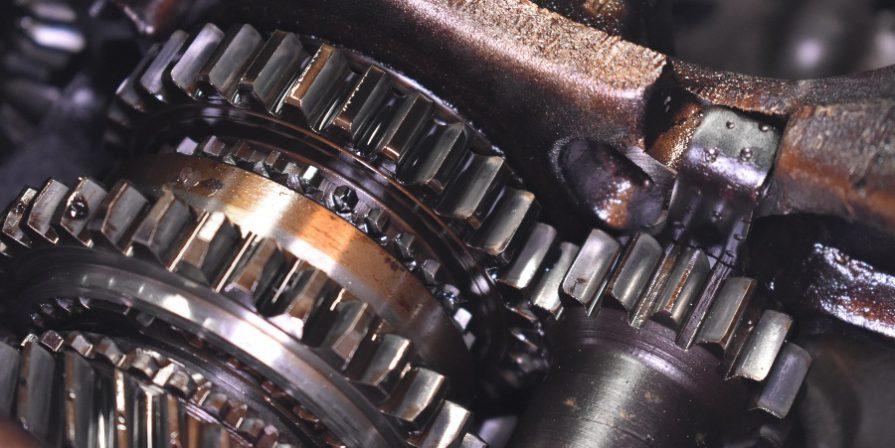

The base body and counter body move relative to each other. This means that either one or both bodies may be in motion. The movement serves either to transport objects or to transmit mechanical energy. This works only if there is direct or indirect contact between the bodies. However, direct contact can occur only at certain points because the surfaces of solid bodies are more or less rough. Under magnification, the contact area looks similar to two metal files pressed together. Unlike files, however, the peaks and valleys on solid surfaces are usually as irregular as a mountain range. Surface technology processes such as grinding and polishing can optimize the roughness profile.

The intermediate medium is a lubricant intended to keep the surfaces of the base and counter body separated. It fulfills this function best when it forms a film that completely fills all surface irregularities. This happens only under ideal conditions. In practice, mixed friction often develops, where the highest peaks of the surface profiles touch one another.

Stress on Components in the Tribosystem

Stress on Base and Counter Bodies

In every tribosystem, a force acts to press the base and counter bodies together. This force must overcome the opposing force that drives the movement. Two resistances oppose it: interlocking surface asperities and attractive forces between the particles of the materials involved. Which resistance predominates depends on the surface profiles and material properties. These factors also determine if material is to be removed from each body, how much will be removed and what happens to it. The removed particles may remain loose or may adhere to the harder material. The various processes of surface technology and surface pretreatment can influence these factors as described in the tribosystem. These processes can create an optimal surface profile, and they can also tailor the surface properties of the materials through the use of appropriate coatings.

Stress on the Intermediate Medium

In direct contact, the intermediate medium (the lubricant) moves at the same speed as the body it touches. Therefore, a velocity gradient develops within the lubricant film. If the film thickness is optimal, the movement force only needs to overcome the internal resistance of the film. This resistance increases with the viscosity of the lubricant. However, if the viscosity is too low, the film ruptures and the surfaces of the base and counter bodies come into partial direct contact — which the lubricant film is meant to prevent. Tribosystem research has enabled the chemical industry to develop and produce optimized lubricants for a wide range of applications.

Stress from the Ambient Medium

Wherever the ambient medium can enter, it may cause chemical reactions. The main factors are the reactivity of oxygen, moisture, and airborne contaminants. Closed tribosystems, such as gearboxes, completely block access to the ambient medium. In open tribosystems, chemistry and surface technology must ensure that lubricants and materials remain protected.

Role of Operating Conditions

How the different stresses affect tribosystems depends on the operating conditions. The most important factors are movement speed and temperature. The reaction of the components depends on how high the speed is, how frequently it changes, and how abruptly or smoothly these changes occur. The energy consumed by friction and wear is converted into heat. The resulting temperature change alters the material properties of the components and the reactivity of the ambient medium. This gives surface technology and chemistry a wide range of challenging tasks.

Cold Bulk Forming as an Example of a Tribosystem

In cold bulk forming, a blank is pressed by a punch against a die. The applied force must be high enough to reach the material’s yield strength. This forces the material to flow into the space between the two tools and take the intended shape. The process is also known as extrusion. In this tribosystem, the die and punch act as the base body, while the workpiece serves as the counterbody. The chemical industry supplies various forming lubricants to function as the intermediate medium and the surrounding air forms the ambient medium. During extrusion, the counter body and the ambient medium are fixed, therefore, optimization efforts focus primarily on the base body and the intermediate medium. The main goal here is to maximize tool life from an economic perspective.

Loads in Cold Bulk Forming

The loads in cold bulk forming are characterized, in part, by the pressing force required and the temperature increase caused by internal friction during the deformation of the workpiece. The tool material must withstand these forces at operating temperature without deforming itself. The forming lubricant must form a stable film under these conditions and must not chemically react with the materials or the surrounding air. Advances in surface technology and chemistry make a decisive contribution to the success of the process.

How Surface Technology Influences the Tribosystem

The high mechanical stress on tools creates an optimization problem that must consider two opposing factors: hardness and strength. The materials used to manufacture these tools are characterized by both their hardness and their strength. High hardness protects the surface against scratches and therefore provides strong wear resistance. However, hard materials are brittle and tend to fracture, especially under varying loads. High strength, on the other hand, protects against permanent deformation. Such tools can compensate for stress through slight elastic stretching or compression, which disappears once the load is removed. They can do this because they are not excessively hard. Surface technology solves this problem through wear-resistant coatings on high-strength materials.

How Chemistry Influences the Tribosystem

The chemical industry is tasked with developing forming lubricants that can withstand thermal and mechanical stress. To do so, these lubricants must be capable of maintaining viscosity even under high pressure and temperature changes. They must also be stable against oxidation and thermal decomposition and exhibit low volatility. Ideally, they are also environmentally friendly and easy to remove from the workpiece. Chemistry achieves this by selecting suitable base oils and combining them with additives to achieve the desired properties.

Kluthe Magazine

Kluthe Magazine